When it comes to securing heavy loads on trailers, flatbeds, or trucks, trailer D rings (also called lashing rings, tie-down anchors, or floor mount rings) are essential for safe and efficient transport. These small but mighty attachments provide strong anchor points for straps, chains, and ropes, ensuring cargo stays in place during transit.

In this comprehensive guide, we’ll explore the different types of trailer D rings, their unique benefits, and how to choose the best option for your hauling needs.

What Are Trailer D Rings?

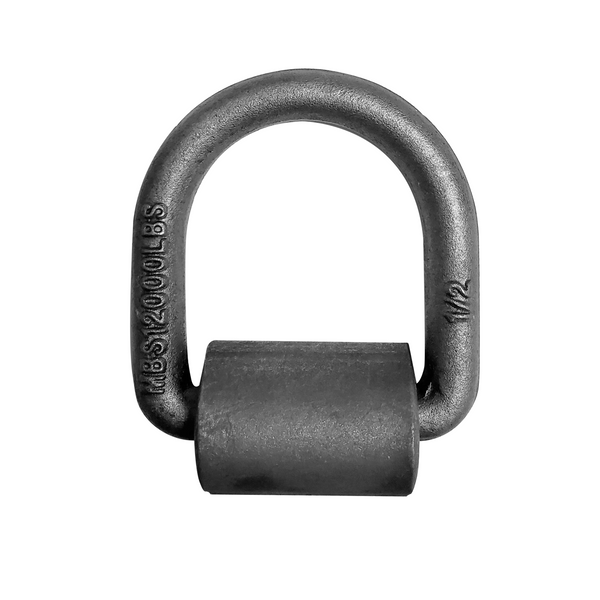

Trailer D rings are heavy-duty metal loops shaped like the letter "D" and are used as tie-down anchors to secure cargo. They are commonly made from forged steel, stainless steel, or reinforced alloy to withstand extreme tension and weight.

Key Uses of D Rings:

- Flatbed trailers – For securing construction equipment, lumber, or machinery.

- Enclosed trailers – To anchor furniture, appliances, or boxes.

- Truck beds – For transporting motorcycles, ATVs, or heavy tools.

- Marine & RV hauling – To keep boats, jet skis, or campers stable.

Bolt-On D Rings

Bolt-On D rings are among the most popular tie-down anchors because of their easy installation and adjustable positioning. These rings are attached using heavy-duty bolts, making them ideal for trailers that require flexible cargo anchoring.

Key Benefits:

✔ Easy Installation – No welding needed; simply bolt them onto the trailer’s surface.

✔ Adjustable Placement – Can be moved or repositioned as needed.

✔ High Load Capacity – Made from forged steel for maximum strength.

✔ Multi-Purpose Use – Great for flatbeds, utility trailers, and truck beds.

Weld-On D Rings

For those who need a permanent, ultra-strong anchor, weld-on D rings are the best choice.

These rings are welded directly onto the trailer frame, making them immovable under heavy stress.

Key Benefits:

✔ Unmatched Strength – Welding ensures a rigid, unbreakable connection.

✔ No Loosening Over Time – Unlike bolt-on rings, they won’t shake loose.

✔ Ideal for Extreme Loads – Perfect for heavy machinery, industrial equipment, and oversized cargo.

Recessed D Rings

If you want a flush-mounted, low-profile anchor, recessed D rings are the solution.

These tie-down anchors are installed into the trailer floor or walls, creating a smooth surface when not in use.

Key Benefits:

✔ No Obstructions – Sit flush with the trailer surface, preventing tripping hazards.

✔ Protects Cargo – Eliminates protruding hardware that could damage goods.

✔ Space-Efficient – Ideal for enclosed trailers where floor space is critical.

Rotating D Rings:

For loads that require adjustable tie-down angles, rotating D rings provide 360-degree movement, allowing straps to be secured from any direction.

Key Benefits:

✔ Adaptable to Oddly Shaped Loads – Perfect for motorcycles, pipes, or irregular cargo.

✔ Reduces Strap Wear – Swiveling motion prevents twisting and strain.

✔ Versatile Positioning – Can be used in corners, edges, or along trailer rails.

Rotating D Rings:

For loads that require adjustable tie-down angles, rotating D rings provide 360-degree movement, allowing straps to be secured from any direction.

Key Benefits:

✔ Adaptable to Oddly Shaped Loads – Perfect for motorcycles, pipes, or irregular cargo.

✔ Reduces Strap Wear – Swiveling motion prevents twisting and strain.

✔ Versatile Positioning – Can be used in corners, edges, or along trailer rails.

How to Choose the Right D Rings for Your Trailer

When selecting trailer D rings, consider these factors:

✅ Load Capacity – Ensure the D rings are rated for your cargo’s weight.

✅ Installation Type – Bolt-on for flexibility, weld-on for permanence.

✅ Trailer Type – Flatbeds, enclosed trailers, and truck beds have different needs.

✅ Environmental Conditions – Stainless steel resists rust in wet or salty environments.

Final Thoughts

Whether you need bolt-on D rings for versatility, weld-on D rings for unbeatable strength, recessed D rings for a clean look, or rotating D rings for flexible securement, choosing the right tie-down anchors is crucial for safe and efficient hauling.

Upgrade your trailer’s cargo security today with the best D rings for your needs!

🔗 Looking for high-quality trailer D rings? Check out our top-rated selection of forged steel, stainless steel, and heavy-duty lashing rings for all hauling applications!