In the fast-paced world of logistics and transportation, protecting cargo from damage is critical. Cargo edge protectors (also called corner protectors) are essential tools that shield shipments from abrasion, impact, and pressure during transit. Whether you're securing goods on a flatbed truck, in a shipping container, or during warehouse storage, choosing the right edge protector can mean the difference between safe delivery and costly damage.

This guide provides a detailed comparison between plastic and steel edge protectors, explains how to select the best option for your needs, and highlights the key benefits of using these protective solutions.

What Are Corner Edge Protectors?

Cargo edge protectors are durable guards placed on the corners and edges of shipments to prevent damage from straps, chains, and rough handling. They work by distributing pressure evenly across the load, reducing wear and tear on packaging while keeping ratchet straps and tie-downs securely in place.

Key Benefits of Using Cargo Edge Protectors

1. Prevents Cargo Damage

Edge protectors act as a barrier against dents, scratches, and tears, ensuring goods arrive in perfect condition. This is especially important for fragile or high-value shipments.

2. Enhances Load Stability

Keeping ratchet straps and chains in place, edge protectors minimize load shifting in transit. This improves safety and prevents accidents caused by unstable cargo.

3. Reduces Long-Term Costs

Investing in quality edge protectors lowers expenses related to product loss, returns, and insurance claims. They also extend the lifespan of packaging materials.

4. Eco-Friendly Options Available

Many plastic edge protectors are made from recyclable materials, while steel protectors can be reused for years, reducing waste. Steel also protect chains in transit.

5. Improves Professionalism & Compliance

Using edge protectors demonstrates a commitment to secure shipping practices. They also help meet DOT and cargo securement regulations, ensuring legal compliance.

Plastic vs. Steel Edge Protectors: A Detailed Comparison

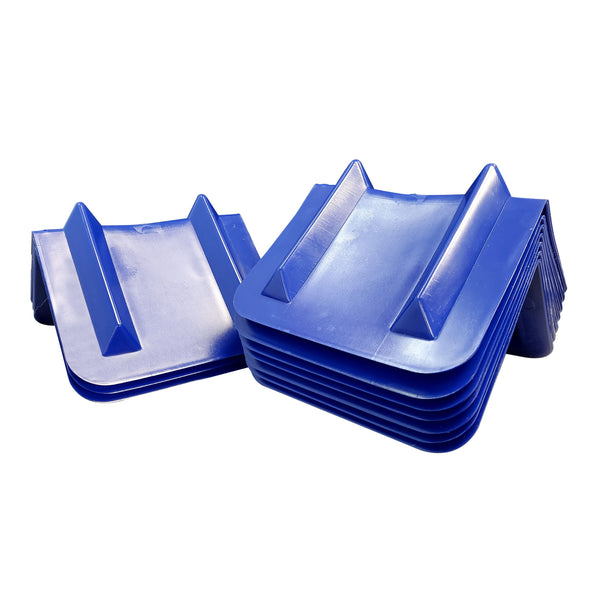

Plastic Edge Protectors

- Best for: Light to medium-duty cargo (boxes, furniture, appliances).

- Advantages:

- Lightweight and easy to handle.

- Resistant to moisture and corrosion.

- Cost-effective for one-time shipments.

- Available in various sizes to fit different strap widths.

When to Use Plastic Edge Protectors:

✔ Light to medium-duty cargo (boxes, furniture, appliances)

✔ Humid or wet environments (plastic won’t rust)

✔ Budget-friendly, one-time shipments

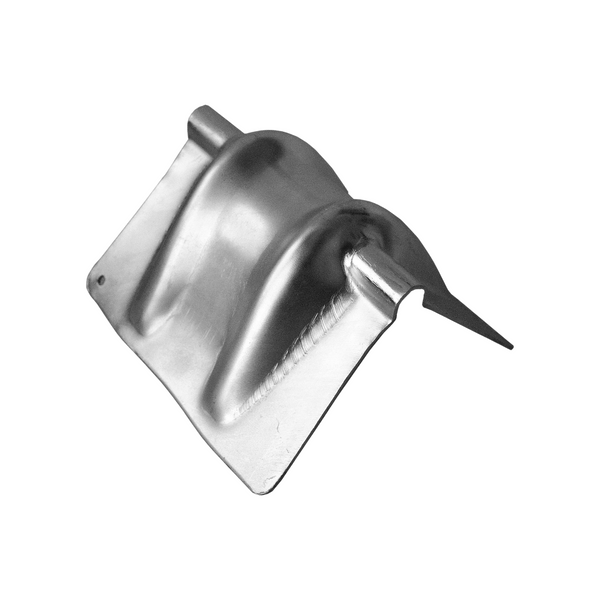

Steel Edge Protectors

- Best for: Heavy machinery, construction materials, and sharp-edged cargo.

- Advantages:

-Extremely durable and long-lasting.

- Withstands high pressure and extreme conditions.

- Steel protectors have a long lifespan and can be reused multiple times, offering exceptional value over time.

When to Use Steel Edge Protectors:

✔ Heavy machinery & construction materials

✔ Sharp-edged cargo (steel coils, metal sheets)

✔ Frequent reuse needed (long-term cost savings)

Final Recommendation: Which Edge Protector Should You Use?

✅ Choose Plastic Edge Protectors If:

- - You need a lightweight, cost-effective solution for standard shipments.

- - Your cargo is vulnerable to moisture or requires frequent handling.

- - You prioritize ease of use and recyclability.

✅ Choose Steel Edge Protectors If:

- - You transport heavy machinery, steel coils, or sharp-edged materials.

- - You need a long-lasting, reusable solution for frequent shipments.

- - Your cargo faces extreme pressure or rugged transport conditions.

How to Choose the Right Edge Protector

1. Evaluate Your Cargo

- - For lightweight or standard shipments, plastic edge protectors are ideal.

- - For heavy or sharp-edged loads, steel protectors provide superior protection.

2. Consider Environmental Factors

- - If shipping in humid or wet conditions, plastic or galvanized steel is the best choice.

- - For extreme pressure or rugged handling, reinforced steel protectors are recommended.

3. Check Compatibility with Straps

- - Plastic protectors typically accommodate 2" to 4" webbing straps.

- - Steel protectors are designed for heavy-duty chains and wide straps.

4. Decide Between Reusable or Disposable

- - If you need a long-term solution, steel protectors offer the best value.

- - For single shipments, plastic or cardboard protectors are more economical.

Cargo edge protectors are a smart investment for any business involved in shipping and logistics. Whether you choose plastic or steel, the right protector will enhance cargo safety, reduce damage, and improve load stability. By considering factors like cargo weight, environmental conditions, and strap compatibility, you can select the best edge protector for your needs.

For high-quality edge protectors and other cargo securement solutions, explore Mega Cargo Control’s product lineup today!

Cargo edge protectors are a smart investment for any business involved in shipping and logistics. Whether you choose plastic or steel, the right protector will enhance cargo safety, reduce damage, and improve load stability. By considering factors like cargo weight, environmental conditions, and strap compatibility, you can select the best edge protector for your needs.

For high-quality edge protectors and other cargo securement solutions, explore Mega Cargo Control’s product lineup today!